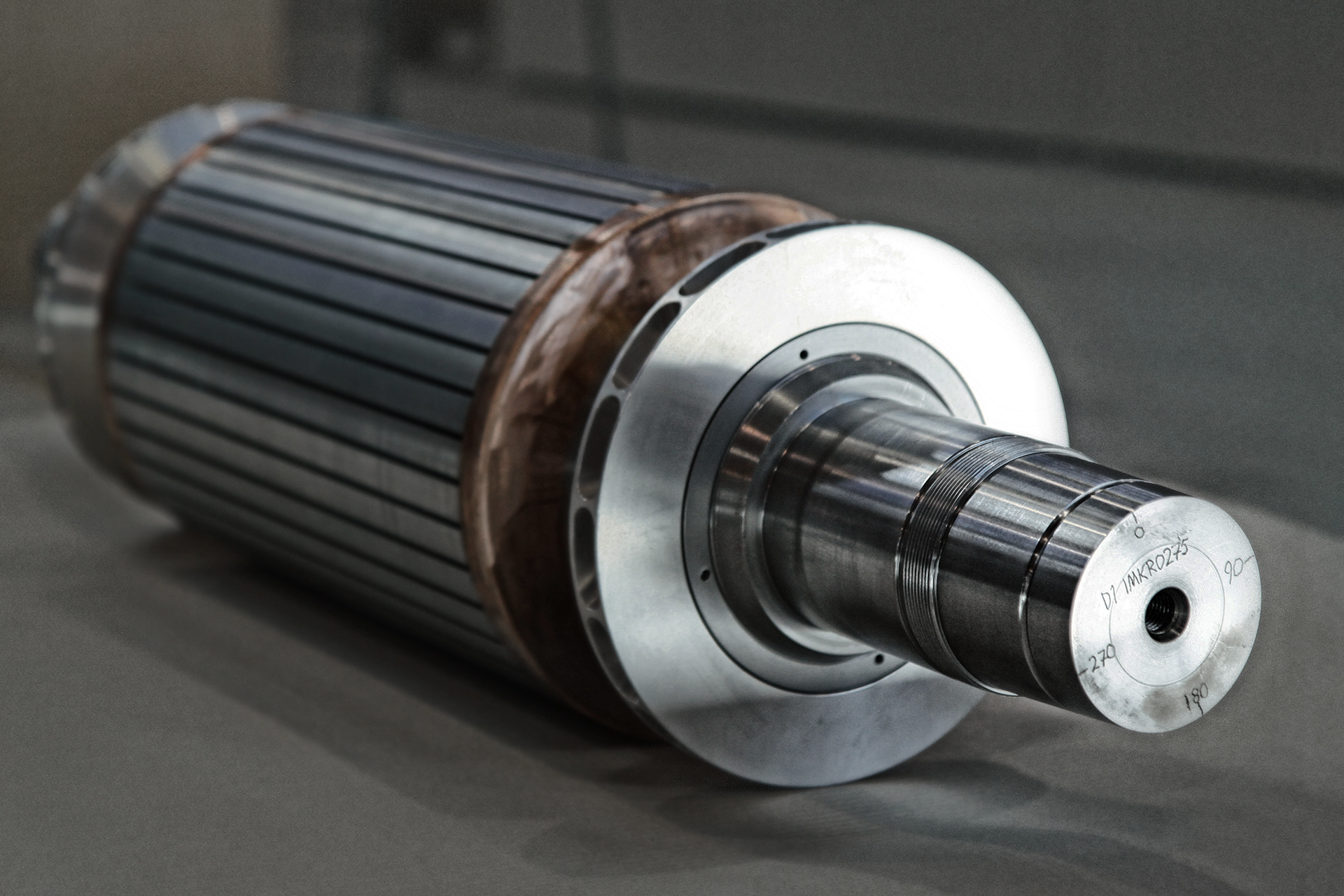

Inter-Turn Short Circuit Fault Detection and Prediction in Induction Motors

Abstract

Induction motors are expensive and the backbone of every industry. There would be no production when induction motors break down. It is also costly to repair them after a sudden shutdown. Industries are gradually adapting to predictive maintenance to prevent unnecessary shutdowns and reduce the cost of maintenance. This paper's objective is to make the predictive maintenance of induction motors more reliable by adding fault detection. This will ensure the reliability of the induction motor, as it will continuously run to increase production quantity and quality while lowering production costs. This project uses secondary stator current data from a three-phase induction motor to detect and predict inter-turn short circuit faults. The stator current data can detect a higher percentage of electrical faults. The predictive maintenance toolbox in MATLAB is used to achieve the fault detection and prediction algorithm. Two classification algorithms, Support Vector Machine (SVM) and K-Nearest Neighbor (KNN) are used to detect and predict the inter-turn short circuit fault. It is found that the selected classifiers of the SVM algorithm gave almost a perfect prediction accuracy as compared to the classifiers of the KNN algorithm. The suggested fault detection and prediction in induction motors work very well, increasing the machine's reliability by decreasing the breakdown time and maintenance cost.